I would like to talk about some things that lie under our feet. These are things that are good for our health and our communities, and they serve us well. These are things to which we generally do not pay attention … until something bad happens.

I am talking about the pipes and mains that provide us clean water, remove our wastewater, and deliver us natural gas for fuel. They are essential parts of city infrastructure throughout the world, and it appears we should be giving them more attention.

A tale of three cities

What are some of the issues facing essential pipes in municipalities? Some selected headlines provide examples.

Boston (U.S.) and area – natural gas pipelines

New gas pipeline rules floated following 2018 blasts in Massachusetts

Vancouver (Canada) – sewer mains

Sewage flows into False Creek after main breaks in Vancouver

Calgary (Canada) – water mains

‘Catastrophic’ water main break cripples Calgary supply, residents told to reduce usage

The Boston headlines describe horrific explosions because of operator error in a natural gas pipeline, and the more passive methane leakage from an extensive network of antiquated pipelines.

The Vancouver and Calgary examples amplify the ongoing break-and-fix cycle of city mains.

All three cities share similar experiences; minor and severe failures of pipe that range in impact from short-term inconvenience to major harm to people and property. Most of us grew up with history lessons of Roman advances in aqueducts and sewers that made their cities flourish. Here we are, thousands of years later, still having trouble keeping city fluids flowing. Are cities getting better at maintaining our services or are we falling behind?

Why things fail

Continued advances in materials engineering and civil design have greatly improved and extended safe service life for our water and gas distribution, but all materials fail over time and need to be replaced. The trick is identifying and controlling the timing of failure. City budgets do not like surprises. Neither do people.

Reviewing the materials used in distribution of gas, sewage, and clean water, there is modern consensus of best practices.

Natural gas – coated steel pipelines for high-pressure transportation, low-pressure distribution can use plastics such as high-density polyethylene (HDPE).

-

-

- Older systems of iron cast piping are still in service, including cast iron (CI), which is vulnerable to corrosion, and the more resilient ductile iron (DI).

-

Sewage and storm water – concrete based conduits are used for larger flow volumes (typically over 0.5-metre diameter), whereas smaller flow/diameter gravity drainage conduits use a wide variety of materials including another useful plastic, polyvinyl chloride (PVC).

-

-

- Many distribution systems have a high legacy amount of vitrified clay pipe, and some still actively install new clay pipe.

-

Treated water – concrete is also used in large-diameter mains, but internal pressures require enforcement with a sandwiched steel pipe and steel wire wrapping: pre-stressed concrete cylinder pipe (PCCP, a.k.a. concrete steel cylinder – CSC). Local distribution uses many materials but mostly PVC and HDPE.

-

-

- Materials such as cast iron and asbestos concrete were used in the past but discontinued due to high failure rates and health concerns, respectively.

-

All these materials have their vulnerabilities to failure. Equipment failures and excavation strikes are common external causes, but the underground environment is also a risk. Here are some highlights:

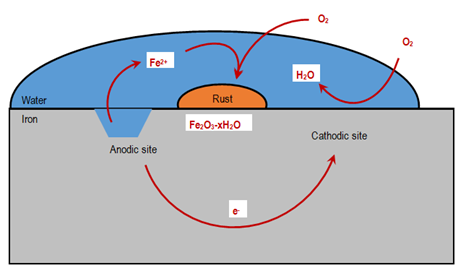

Metal (Iron) corrosion

Corrosion is the degradation of metal through reaction with the environment. For iron and steel, contact with water and air stimulates an electrochemical reaction. Iron combines with oxygen and water to create rust. The result is strong metal transforming (oxidizing) into flaky rust. Oxygen-free environments are best for metal, but corrosion can be mitigated by applying external surface coatings, regular cleaning/coating of internal surfaces, and applying a cathodic current to counter the natural electrochemical tendencies.

Alternative metals such as copper are more resistant to corrosion but prohibitively expensive to be used extensively.

Steel + Water + Oxygen = Rust

Steel + Water + Oxygen = Rust

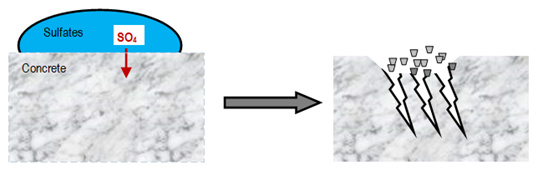

Concrete corrosion

Basic concrete is aggregate material bound by cement of specific proportions. Common constituents within the binding matrix are sensitive to sulfates (SO42-) from alkali soils, water, or sewage. Air and water liberate and transport sulfate ions into direct contact with cement matrix, which hydrates specific ingredients forming crystallizing ettringite and/or gypsum. Both cause expansion and cracking. Cracks in concrete allow for greater exposure of the concrete to harmful elements, and the deterioration accelerates.

Cement + Sulfate Ions = Gypsum + Ettringite

Plastic and clay failure

These materials are generally chemical resistant, but are more brittle, and plastics have less burst strength. Service failures outside operator error, and natural strikes include root invasion and ground heaving.

How bad is it?

The rate or frequency of failure in municipal piping depends on the material and time in service against environmental factors such as external soil chemistry, fluid chemistry, pressure, and temperature, as well as human-based factors such as installation practices and ongoing maintenance.

While many jurisdictions manage their own integrity data in varying quality and accessibility, there are agencies and institutions that endeavour to gather a representative portfolio of pipe service and failure data to analyse.

Natural gas distribution

Analysis is focused on natural gas distribution (delivered to customers) excluding natural gas transportation (between gas wells and facilities). Energy producers and midstream operators are heavily regulated and actively maintain their high-pressure transportation systems, whereas the gas distribution systems are operated by cities and utilities under different levels of bureaucracy and budgets. Analysis on distribution-based facilities is hampered by lack of open data (or meaningful data) at the city level.

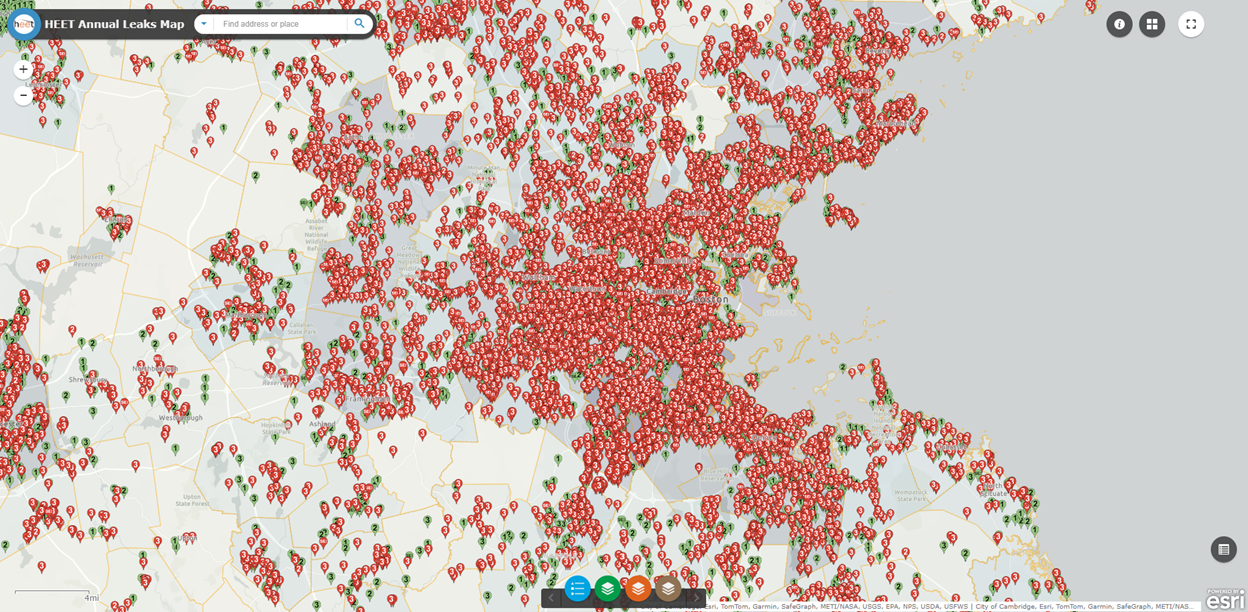

In the Boston example, there is no open data source apparent to assess local pipe materials, break history, and other meaningful indicators of system health. Outside agencies and groups have been able to secure their own data and assessment including non-profit group HEET, which undertook a methane-leak-mapping project to assist identification of the worst offending leaks for repair or replacement. This is used in efforts such as the Gas System Enhancement Program, which accelerates gas line replacement in Massachusetts. A snapshot of the online leak map provides a visual of progress on resolving the outdated gas system (red being active leaks, green repaired).

From the map above, you can conclude Boston (centered on map, hidden by all the leaks) has a big job to tackle. Apart from the passive leaks, there is also a question of whether antiquated gas systems harbour more serious risk. A regional/national look at natural gas pipelines provides more meaningful data to assess.

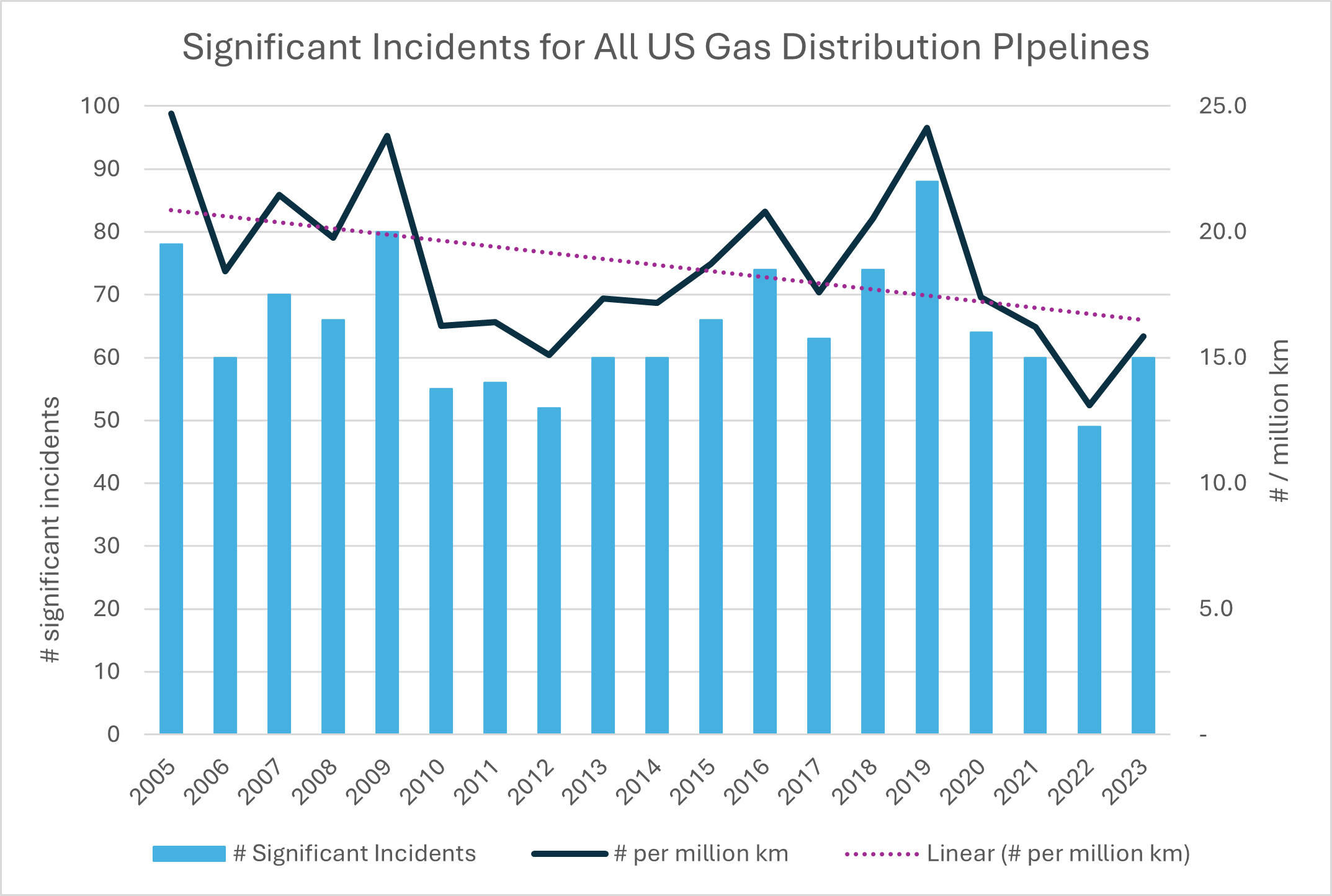

The US Department of Transportation reports a total of over 3.5 million km of natural gas distribution pipelines across the country, with annual significant incidents (breaks) numbering between a low of 49/year and high of 88/year during the 2005 to 2023 reported period. Significant incidents include gas pipeline failures resulting in serious impacts such as evacuation, harm to people, and property damage. The ratio of incidents to the extensive network of pipe results in a range of 13.1 to 24.7 incidents per million km (21.1 to 39.7 per million mi) and a median of 17.6 incidents per million km (28.3 per million mi). As shown in the chart below, there is linear trend improvement (lower incident ratio) over the period. During the same period, the total pipeline system increased by 20%, which indicates some efficiency is being achieved, perhaps from efforts such as the Boston example of replacing or discontinuing deficient pipe. Unfortunately, additional data such as incidents by pipe material were not accessible for detailed review.

Wastewater distribution

Local city data sets provide insights into the state of city water pipes, but leave gaps in understanding the state of systems.

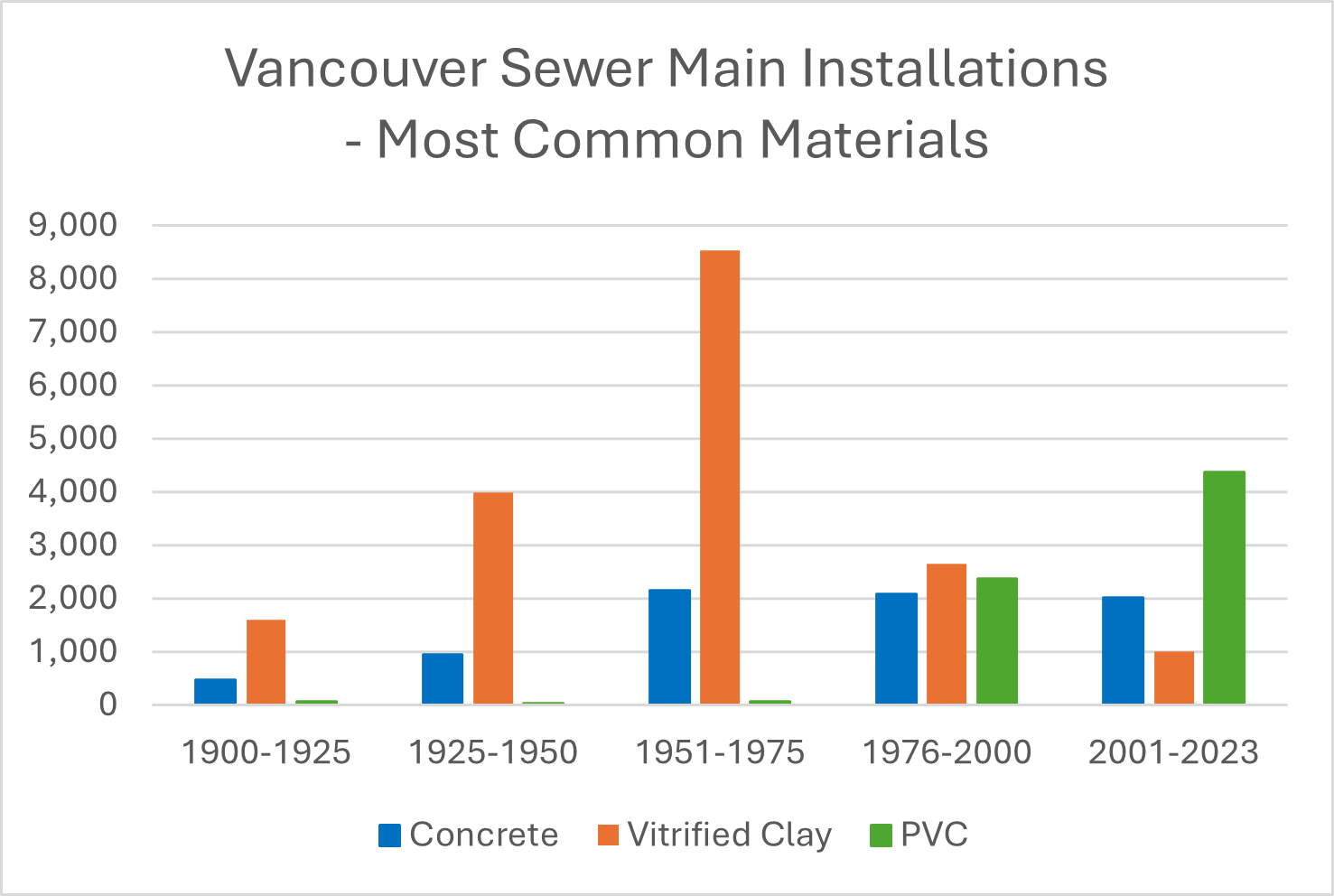

A review of the City of Vancouver sewage and storm database shows a variety of materials used in infrastructure, with the most common identified materials as concrete (mostly for diameters larger than 0.5m), vitrified clay, and polyvinyl chloride. Recent years show PVC as the preferred material for smaller-diameter pipe, outpacing clay installs in the last 20 years (last clay install reported in 2019). Unfortunately, a corresponding pipe-failure dataset was not available to confirm if the increase in PVC pipe is an economic choice or based on engineering concerns.

A wider search for regional or national data on sewer-main materials and breaks was not successful in time for this article. The assessment of treated water-main data was more fruitful and has data for material conclusions.

Treated water distribution

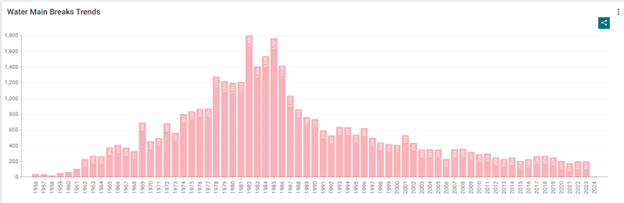

Being a relatively young and growing city, Calgary has an extensive network of water mains that have been actively upgraded. City data even provides an appearance of manageable break and repair history, but these still have frequency in the hundreds of breaks per year.

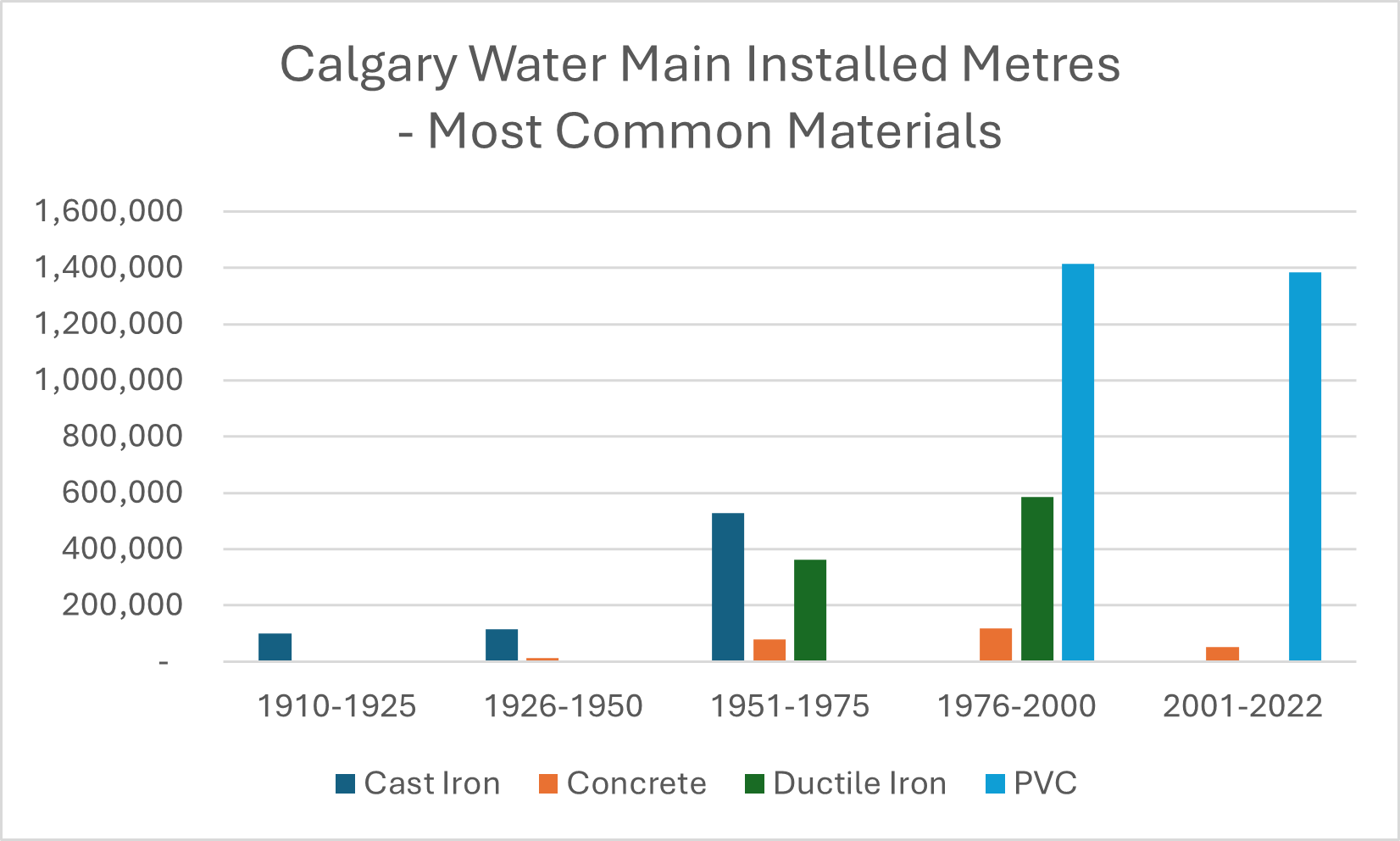

Materials data from the City of Calgary shows a familiar shift from ferrous-based materials to PVC for water pipes. Concrete-based mains have a modest proportion of installed length, but are usually the largest-diameter feeder mains.

Calgary’s issue in June 2024 involved a large water main (up to 2m diameter) running 11 km made of PCCP that serviced 1.2 million people. Failure analysis could take months to confirm pipe sections that lasted approximately 50 years of their anticipated 100-year life. Implications are costly as replacement for PCCP can be over US$1 million per km, and the City reported 187 km of PCCP mains installed and 518 km of total concrete-based materials. (Note: Calgary reported the total PCCP length on its website, but city data does not identify PCCP-specific installations and does not corroborate.)

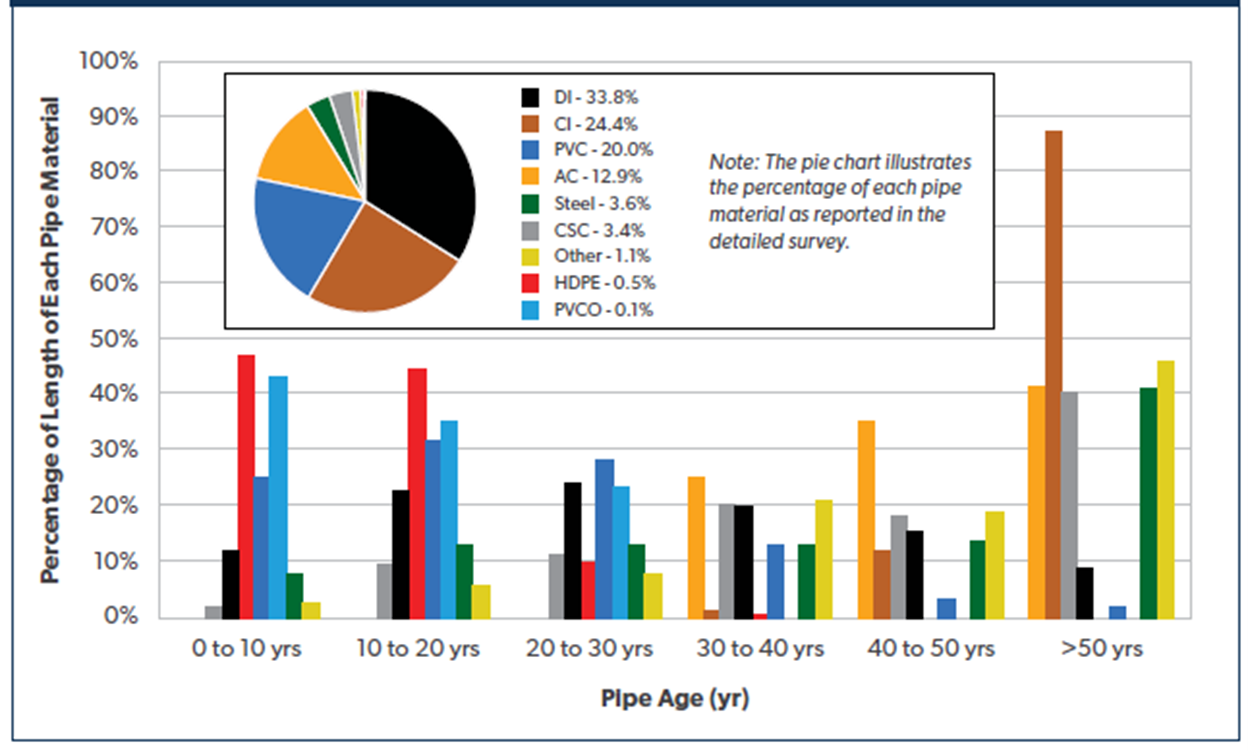

Taking a wide view of water-main integrity, the Utah Water Research Laboratory (Utah State University) published a December 2023 study of water-main breaks that used survey respondents from 802 entities in the U.S. and Canada that accounted for 17% of the total water-main pipe length in those countries. Although a minority of the water systems are represented, the regional spread and amount of data is statically significant, and some relevant observations can be made.

-

-

- New installation has skewed to polymer-based HDPE and PVC materials, with asbestos cement and cast-iron materials being phased out.

- Significant amounts of older pipe materials include CI, which is more prone to corrosion.

-

-

-

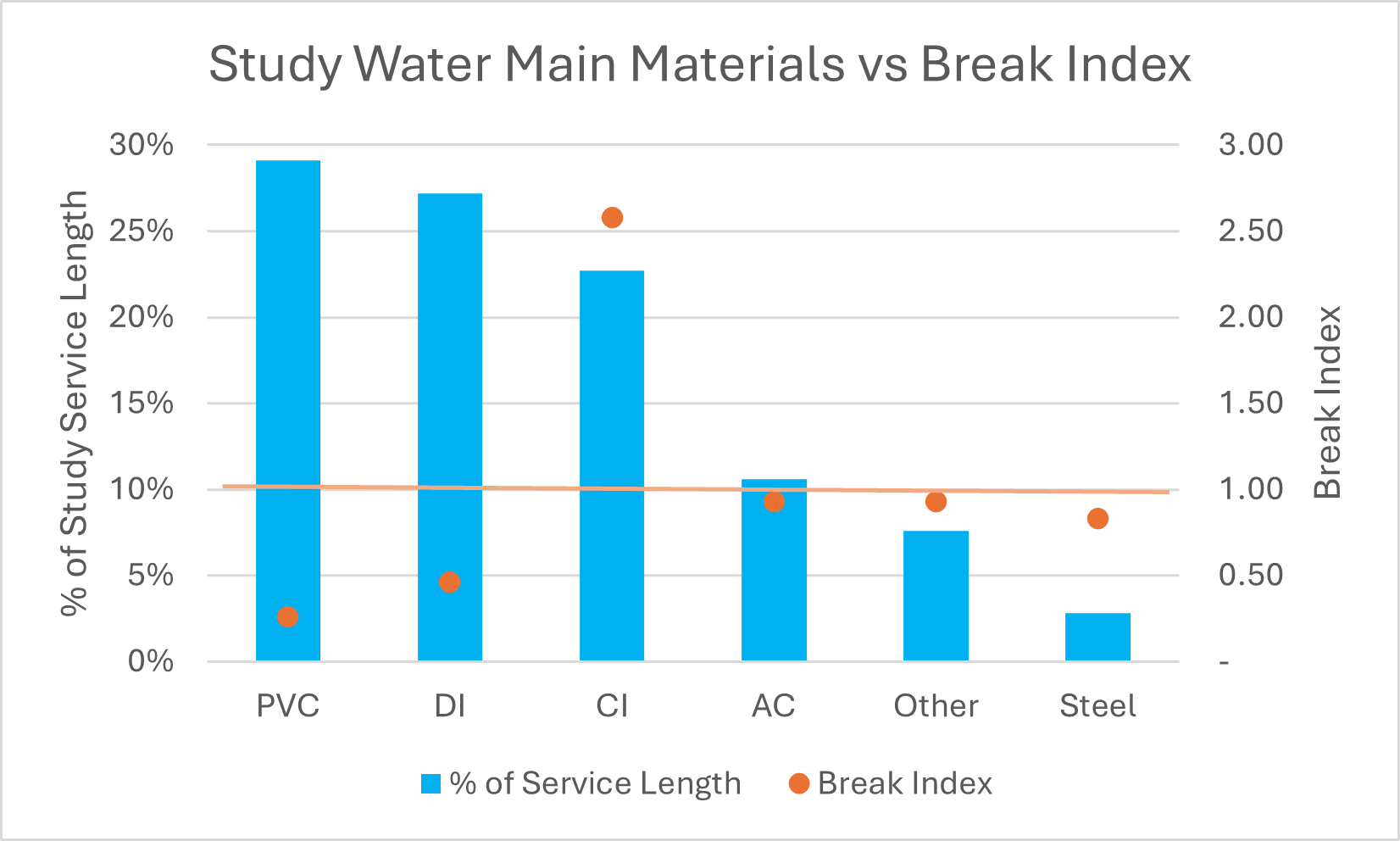

- Comparing the most common materials by total in-service volume to relative break history, PVC and DI stand out for low failure rates and support the high and growing install proportions, and high failure rates for CI are confirmed.

- Break Index is a relative comparison of materials: dividing 2023 break rates by material by the average study break rate of 11.1 breaks per 100 miles.

- PCCP (or CSC) was discussed in the report and represents 2.8% of service length but the break data was not accessible (included in other).

- Comparing the most common materials by total in-service volume to relative break history, PVC and DI stand out for low failure rates and support the high and growing install proportions, and high failure rates for CI are confirmed.

-

Conclusions

-

- Although older cities such as Boston appear to have “all hell for a basement,” ongoing efforts are being put into upgrading and modernizing natural gas pipe and systems for safer use of fuel.

- Municipal data systems are sporadic and inconsistent. National initiatives would be required to gather and disclose meaningful data to the public and keep local administrations “honest” in addressing asset integrity.

- Engineering practices have evolved to utilize better materials and installation practices for longer service life. However, legacy systems are problematic and require extensive spending to replace.